As the Internet of Things continues (IoT) continues to grow in the consciousness of consumers and IT experts alike, thought is increasingly turning to how to ensure that its promise delivers on its potential.

The benefits of IoT are clearly significant. From the advent of ‘smart homes’ where fridges can restock themselves when supplies are low, to the increasing prevalence of wearable tech that links to smartphones in the field of health and fitness, IoT is changing the way we live and work at a rapid pace, says Dirk Paessler is CEO of Paessler.

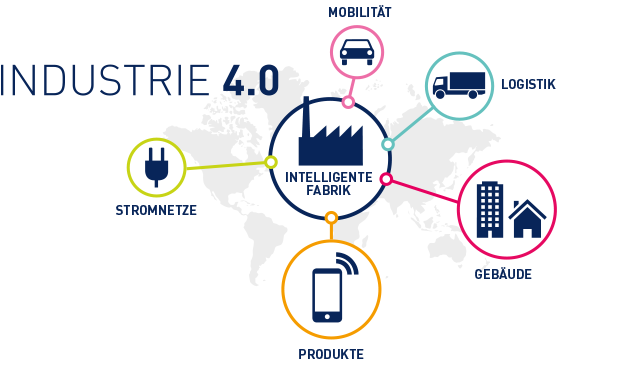

However, particularly in a business context, IoT also has a number of challenges to contend with if it is truly to revolutionise the modern workplace. Take an IoT-enabled factory for instance, where there will be a large number of industrial machines that are able to talk to each other and self-diagnose operational problems. This is a lot of things to connect, and takes careful consideration on the part of the IT team to ensure that everything runs smoothly.

The shift to smart manufacturing

The migration to smart manufacturing, also referred to as the Industrial Internet of Things (IIoT), is a hot topic in industry right now. Ultimately, the primary goal of IIoT is to create a context in which machines can communicate with each other without the need for mediation by a human being. In these circumstances, data would be collected from machines and analysed to drive efficiencies, thereby reducing cost. Logistics would become more automated and optimised, resulting in more intelligent and flexible production.

The advantages of IIoT are clear for all to see. If all is done correctly, an assembly line would never be forced to deal with downtime thanks to machinery that can anticipate when it needs new parts, and effectively repair itself.

Another, peripheral benefit would be significant progress in the field of health and safety, as wearable technology becomes more prominent in the B2B space. The advantage of technology that can measure temperature and noise exposure and alert workers before their environment becomes unsafe would be hugely valuable.

Switching to a new infrastructure

However, making IIoT work is not as easy as flicking a switch. A number of obstacles stand in the way of its success, not least the fact that it will throw up a series of problems for IT departments, from the complexities associated with switching to a new system to the sheer number of connected devices that will need to be kept in check.

The most effective way to mitigate these risks is through the implementation of an appropriate IT monitoring solution, which provides an integrated view of a company’s entire IT infrastructure. However, before choosing a solution, there are a number of IIoT-specific requirements to look for, such as:

- Support of common standards for IT monitoring

- Documented interfaces for integration of the various production systems

- Efficient, user-friendly representation of monitoring data via dashboards and notifications

- Extensive alarm and reporting features

Benefits for distributed networks

An additional consideration when choosing an IT monitoring solution for an IIoT-enabled factory is the ability to monitor across a multi-site network, given that many large factories will be spread out across several different locations.

IT monitoring can be a particularly useful resource for IT teams when it comes to major transformations such as a shift to IIoT, particularly across several sites. Organisations often struggle to deliver high ROI with limited resources, but providing IT staff with a control panel through which they have an overarching view of the network can help ensure a successful IIoT infrastructure.

Achieving potential

The potential for IoT to change the face of industrial manufacturing is clearly huge. However, its success ultimately depends on the delivery of a dependable and high-functioning network that can ensure its smooth running. The benefits of IIoT are obvious, but clearly thought needs to go into how it can be made to work effectively, rather than simply what it is able to deliver.

The author of this blog is Dirk Paessler is CEO of Paessler

Comment on this article below or via Twitter: @IoTNow OR @jcIoTnow