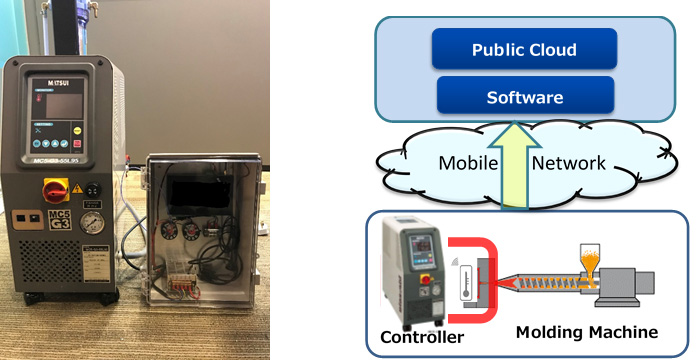

Matsui MFG. Co., Ltd., NTT DOCOMO, INC. and NTT DOCOMO ASIA Pte. Ltd. announced that they will launch a proof-of-concept demonstration of an IoT platform for plastic-molding operations using a mold-temperature controller equipped with sensors and connected to a mobile communications network, enabling production data to be sent to a cloud server for real-time processing. Beginning November 15, the demonstration will help to confirm system accuracy and related issues for an envisioned commercial solution, expected to be the world’s first of its kind, for highly efficient plastic molding applications in Southeast Asia’s fast-growing industries for automobiles, electrical appliances and other products.

The solution will incorporate the use of a mobile-connected mold-temperature controller, built specially for the demonstration, at a plastic molding factory in Indonesia.

The controller collects data via sensors and then communicates the data via a mobile network for real-time visualisation and analysis. IoT-dedicated software will connect the sensors to a public cloud via a mobile network, or potentially a low-power wireless access (LWPA) system. Manufacturers are expected to use the platform to reduce machine downtime due to various malfunctions, prevent production defects and improve production processes.

Through the demonstration, the three partners will determine the possibilities of acquiring and visualising data suitable for extra-efficient plastic-molding production. In the future, machine learning and artificial intelligence are expected to be incorporated in the platform for increasingly efficient production operations.

In preparation for an envisioned commercial launch, Matsui will continue to enhance its mold-temperature controller, sensors and related know-how, DOCOMO will develop practical IoT services for Southeast Asian industries and DOCOMO ASIA will continue to enhance the IoT-solution platform for deployment in Southeast Asia.

Factors such as mold-temperature control, screw speed, pressure, etc. greatly affect the quality of plastic molding, creating the need for high-precision IoT-based production platforms.

The demand for plastics in Southeast Asia’s manufacturing industry is expected to show robust growth due to factors including regional population growth, expanding operations by Japanese automotive, electric, and other manufacturers, and ongoing efforts to reduce product weights and production costs.

Comment on this article below or via Twitter: @IoTNow_OR @jcIoTnow