Here at Momenta Partners, we spend a lot of time speaking with innovators and end users about how to harness data from physical assets to optimise processes, reduce risk, grow businesses and even power brand new business models, says Ed Maguire, Insights partner.

Predictive Maintenance is top of mind across the board, with start-ups, professional service firms and established industrial firms seeking ways to realise benefits by “fixing things before they break” – potentially saving massive amounts of time, money and reputational risk.

What is Predictive Maintenance?

Predictive Maintenance involves simply being able to predict when a machine or part is likely to fail based on real-world data, then being able to take action to avert any problems. This is a simple concept, but difficult to realise. In industries like aerospace and transportation, being able to prevent failures can save lives.

While the recent Southwest Airlines fatality may not have been foreseeable, what if the data from the engine explosion could be used to prevent the next one? To be able to predict a potential failure, you need to start with data – historical data, particularly leading up to a failure – in order to create an algorithm that can flag signs of pending problems.

The path to Predictive Maintenance

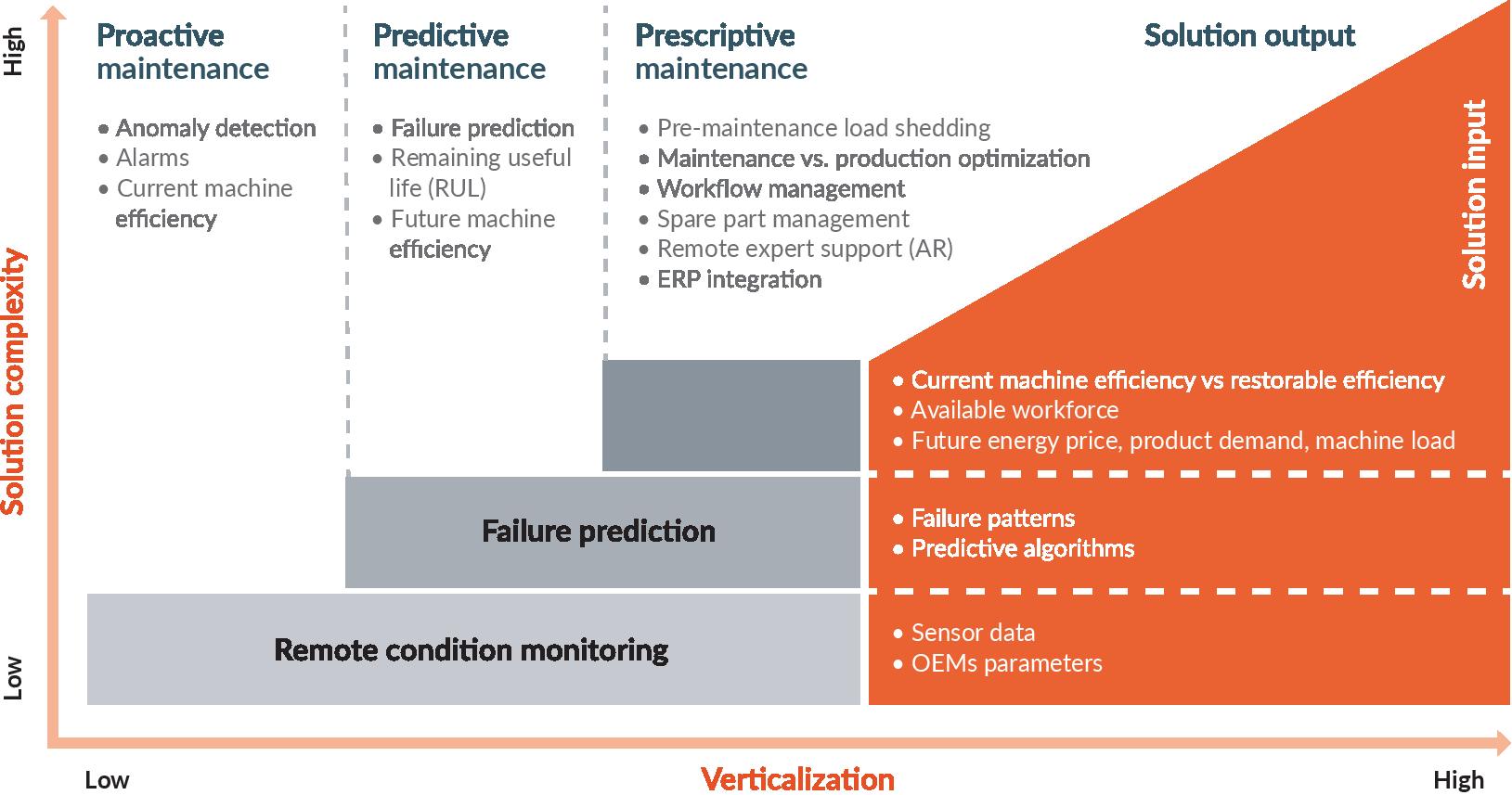

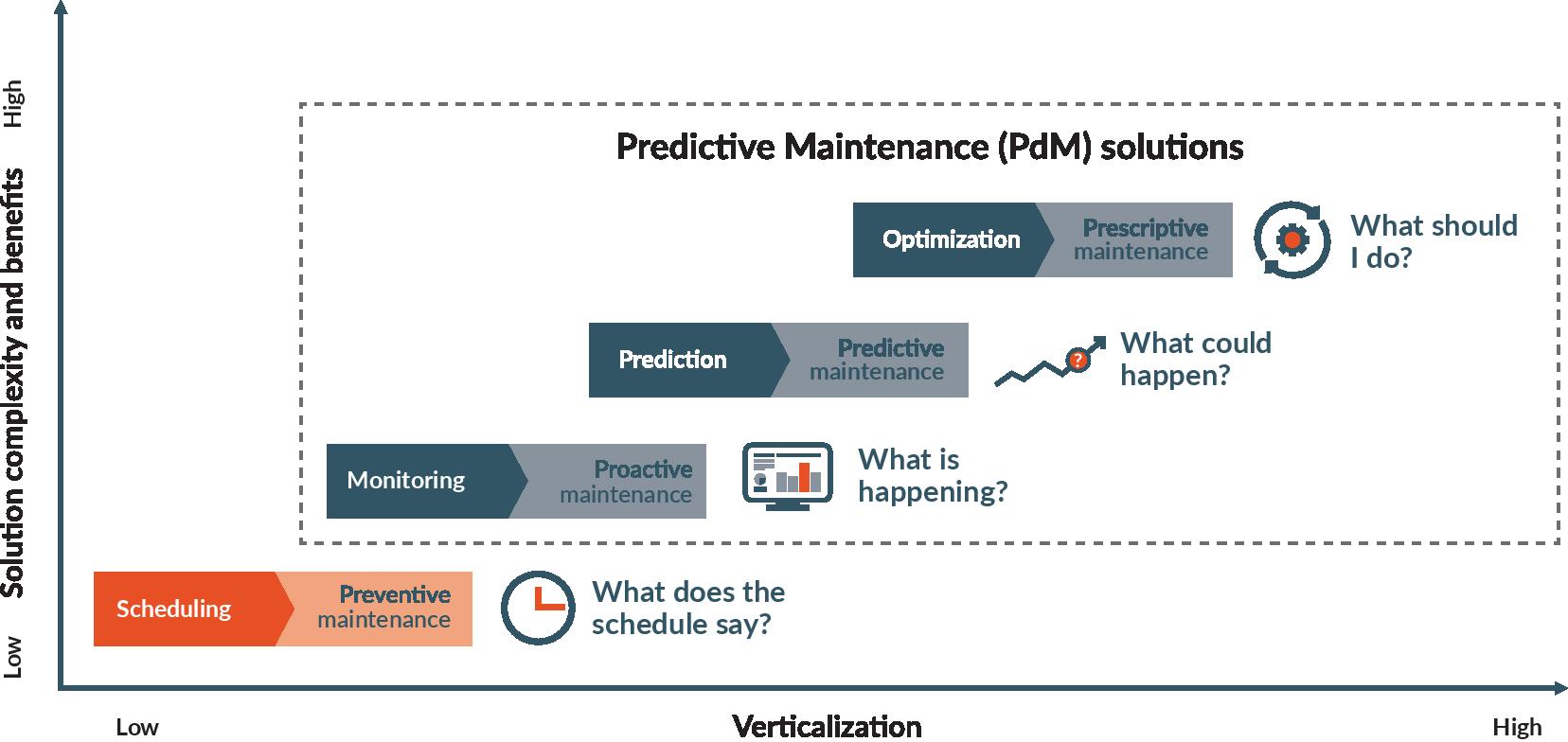

Today industrial maintenance is mostly “preventive” in nature. Prevent Maintenance starts with a schedule. When firms purchase industrial or other assets, they typically follow recommended intervals for maintenance. Think about the recommendation to change the oil on a car every 3,000 miles. Outside of keeping to the prescribed schedules, most major repairs happen when there’s equipment failure, and assets themselves are replaced when they reach a certain age. Keeping to a schedule is useful, but it doesn’t provide an idea of what could happen in the future.

With the addition of Condition Monitoring, businesses can engage in Proactive Maintenance. Condition Monitoring involves tracking data in real-time – this could be data from temperature or vibration sensors for instance. This can help identify problems as they occur, and if there’s an unusual condition such as excess vibration or overly high temperature this can signal the need for proactive maintenance – a change of a part for instance.

Preventive Maintenance works from a predefined schedule, and Proactive Maintenance typically employs Condition Monitoring but neither approach will necessarily help a business anticipate what is likely to go wrong in the future.

To be able to predict failures, you need historical data to develop a predictive algorithm, preferably including periods leading up to and including failures or breakdowns. The involves collecting the data and performing analytics on the data, then testing, tuning and updating the algorithms with newly collected data. In this past this was an expensive process, that demanded highly specialised statisticians who could develop specialised models.

Once Predictive Maintenance solutions have been in place for some time, they can be couple with specific recommendations or instructions for the business to fix the problems before they occur. This concept, known as Predictive Maintenance, is the idea that analytics can identify pending problems, guide a fix, and keep machines up and running with minimal human intervention.

Since the 1980s, Predictive Maintenance had been the province of the largest organisations with the deepest pockets where there’s a high cost of failure or downtime such as the military and in aerospace. Today with the massive price declines in storage, processing power, specialised chips such as GPUs which are suited for Machine Learning, the accessibility of Predictive Maintenance is becoming democratised.

The reality today is that many assets are over-maintained, with companies spending needlessly in order to prevent failures because they lack insights into the actual health of machines. There’s tremendous opportunity to reduce costs from downtime and disruptions, as well as spending far more efficiently on how often and how extensively machines are repaired. While we are still in early days, with most industrial firms moving from Preventive to Proactive Maintenance, there are a wealth of start-ups and projects underway to democratise Predictive Maintenance.

It’s critical to start with the data, so we recommend a measured approach. Start with Condition Monitoring, and ensure comfort and accuracy of the data and processes. Once there’s reasonable Proactive Maintenance tasks in hand, then engage data and domain experts (either data scientists for do it yourself, or specialists in your industry from a professional service firm or software start-up).

Develop the algorithms, test them out in real life, measure, tune and upgrade and continue the process. Predictive Maintenance is goal, but it’s more of a journey than a destination. There are loads of resources and experts available to help out, and with persistence will come success – cost savings, elimination of unplanned downtime, improved safety, more efficient processes – and happier customers above all.

To find out more, we recommend reading Realizing the Opportunity in Predictive Maintenance (PdM) Analytics.

The author of this blog is Ed Maguire, Insights partner at Momenta Partners

About the author:

Ed brings more than 17 years of Wall Street experience in equity research and investment banking to Momenta, with deep domain expertise in enterprise software. He has proven success identifying strategic opportunities and articulating actionable insights based on rigorous analysis of technology, operations, competition and markets. Most recently he was senior analyst and managing director at CLSA Americas covering the software industry, technology and innovation.

Comment on this article below or via Twitter: @IoTNow OR @jcIoTnow