Dr Janos Veres, who leads Parc’s Novel and Printed Electronics programme, looks at turning printing into a manufacturing technique for electronics to meet the needs for Internet of Things (IoT) applications. Electronics is entering a new era driven by the rapid rise on the IoT. Wearables, automotive and the vast range of IoT applications cannot be served by traditional electronics-in-a-box solutions and we need to go beyond simple mass production of electronics and begin to address unique, customised devices that are made on-demand.

A key enabler for this transition is flexible and conformal electronics. For the last couple of decades, printed and flexible electronics was viewed as a low-cost manufacturing option for mass products such as displays, RFID, sensors and interface panels. Automotive companies began experimenting with in-mould electronics, while printed memory emerged that could be manufactured with existing tools.

But the challenge of delivering cost and performance in competition with well-established products and processes has been significant. More recently, we have seen new opportunities for flexible, printed and hybrid electronics to deliver niche products and unique form factors.

Internet of smart things

The concept of printable electronics is an important enabler for mass customisation of electronics to create an internet of smart things that fuse form and function in new ways. The most important shift that has occurred is the realisation that we should not try to beat silicon but instead, use it as part of our toolkit.

Printing then becomes an integration technique to deliver unique form factors with the integration of soft and hard materials and components, enabling customised, on-demand products at low cost. The use of new materials and freedom of design is exciting for manufacturers. For example, smart packaging is emerging as companies such as Thin Film Electronics and PragmatIC experiment with the integration of NFC (Near Field Communications).

Sensors and data processing integrated into packaging can also allow the monitoring of environmental parameters. For some pharmaceutical products, for example, monitoring temperature, humidity or carbon dioxide levels is particularly valuable. With smart packaging, a whole array of benefits emerges from increased product quality, reduced waste and simplified inspections to dynamic repricing and time and cost savings.

Even stretchable electronics

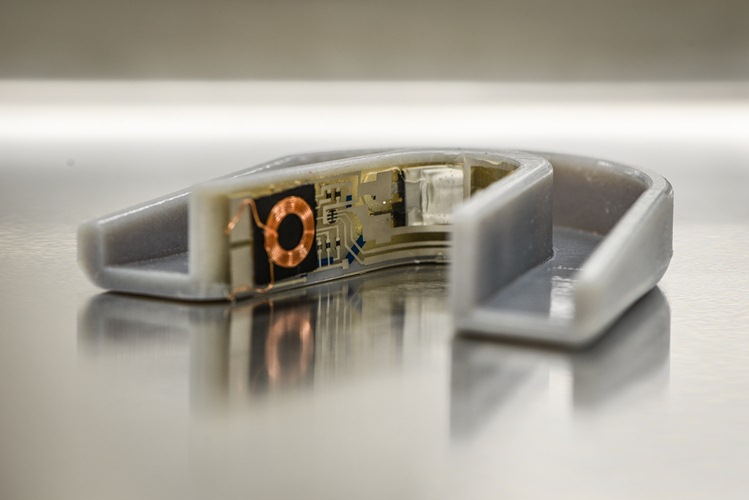

In the future, we see flexible hybrid electronics (FHE) systems becoming widely established where printed multilayer PCBs with thinned chips give rise to flexible, soft and even stretchable electronics. Printing is significant because it enables on-demand fabrication on much larger areas and enables complex integration layer by layer.

This means that printing has the potential to become a valuable manufacturing technique for a multitude of electronics and IoT devices, all the way to flexible personal devices of the complexity of a mobile phone.

Many challenges still need to be solved before we get there. New materials are needed that play together well and provide alternatives to costly elements such as silver. Printed copper is one example, but we will also see creative solutions based on other materials.

Stretchability is another challenge that needs to be tackled by material science. Our boldest prediction is that we might turn microchips into inks and print with them. This is a radical concept that will enable rapid, on-demand fabrication of complex circuits but it will require new approaches to circuit design.

The future is printed

Overall, we envisage a printed FHE future taking us closer to create custom solutions to things, small or large, embedding intelligence in the fabric of devices around us. We will see a multitude of sensors embedded in automotive or aerospace frames to enhance safety.

Soft robotics and prosthetics are other areas as well as custom smart patches monitoring your health. Importantly, we envisage that designing and fabricating such components will become simplified and accessible, enabling an accelerated path for the overall progress of electronics and the IoT.

The author of this blog is Dr Janos Veres of Parc

Comment on this article below or via Twitter: @IoTNow_OR @jcIoTnow