Real-time monitoring of the condition of equipment enhances effective decision-making in terms of machine maintenance and operational efficiency. This study presents a multi-layered system architecture to monitor the real-time health of a sensor-integrated hand-tool.

Abstract:

Real-time monitoring of the condition of equipment enhances effective decision-making in terms of machine maintenance and operational efficiency. This study presents a multi-layered system architecture to monitor the real-time health of a sensor-integrated hand-tool. The architecture is designed based on specific components, features, and requirements of each layer. The study discusses the flow of information in the system and addresses compatibility issues. The selection of required hardware and software was made based on the applicability and compatibility of various available alternatives. The selected modules were a sensor unit, an open-source IoT Platform, and a Wi-Fi Module. A prototype of the sensing unit was developed and was integrated with the tool for conducting the experiments to acquire the vibration data. The experimental setup was designed, and the free-run mode and drilling-mode acceleration data were generated. The obtained real-time acceleration plots indicate that the overall IoT system performed as intended. The quality of the data was verified using the Western Electric rules. The study extends the framework to a warning system using a freeware web-service, which operates sequentially. Upon arriving at the threshold value of acceleration, the web-service automatically sends a warning message to the maintenance team for on-time maintenance.

Introduction

“Global Construction 2030” estimates the construction output to grow by 85% worldwide by 2030 [1]. As per the empirical data and prediction of this study, this growth will be accompanied by the increasing use of small power tools that are essential to improve the productivity of the workforce. As practical experience and productivity logic demonstrates, timely and continuous availability of the tools ensures uninterrupted work at the sites. The relevance of smooth-functioning machines in operational sites may be derived from the survey conducted by one of the leading asset manufacturers Hilti Corp., which clearly quotes that “On average of 90 hours a month are spent searching for assets across construction sites.”.

Apart from theoretical study and predictions, industry professionals also equate the loss in productivity with mismanagement of power tools, which results in tools going unaccounted and undocumented or noticed only when there is a requirement of the machine, thus furthering machineattrition, waste, and loss of time. These seemingly minor losses can cumulatively result in overall delays in the project, causing heavy monetary and reputation loss. Addressing such loss is thus imperative from an academic as well as industry point of view. The mismanagement can be due to inconsistent implementation and monitoring.

implementation and monitoring. Tools that are not maintained properly can perform below par or disrupt work through breakdowns, adversely affecting, not just their own functions but also of the interconnected tasks. As evident from most of the studies, most construction sites lack a systematic surveillance and maintenance strategy [3]. Currently, the best practices in tool maintenance rely on periodic maintenance either as specified by the manufacturer or when there is an apparent malfunction. However, technological advancements have made it possible to monitor and calibrate the characteristics of a tool in operation in more reliable, robust, and consistently cumulative manner. Based on the pattern changes in functioning tool characteristics; proactive and preemptive maintenance measures may be taken to resist machine attrition. Such measures can minimize operational interruptions and ensure the optimal performance of tools and workforce.

The objective of the study is to develop and test a framework for an IoT Enabled predictive maintenance schedule using real-time data. This will also facilitate remote monitoring of assets, making decision-making more efficient and rational. Most importantly, it willaspire to offer a model that may be mapped on to complex situational systems, ensuring optimal machine productivity and safety with multiple monitoring frames

As per a survey on power tools, drilling machines are among the most widely used hand tools in the construction industry [4]. As drills are constantly utilised on demanding tasks, they tend to require constant monitoring and maintenance to ensure the best performance. The scope of the current study is limited to the monitoring of hand-held drilling machines.

In terms of structure, this paper is broadly divided into four sections. The first section reviews the current practices in the field of equipment health maintenance. The second section explains the system architecture and design. This section explains the individual layers and their components and the flow of data across them. The third section studies the various parameters that affect the health of the machine. This section also describes the experimental setup and documents the results obtained. The final section discusses the results and intends the integration of the proposed framework with MathWorks’ ‘Predictive Maintenance Toolbox’ and its use in Machine prognostics. This section concludes the study with discussion on the future research scope in the domain of maintenance studies.

Review of Maintenance Planning

This section presents a brief review of maintenance planning and discusses the potential of IoT technologies for construction management.

Maintenance Planning

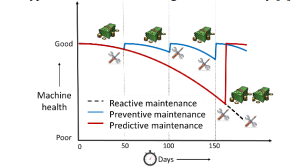

Equipment require maintenance due to various factors, ranging from systemic to situational. Usage patterns and ageing of the machine are key factors causing a decrease in reliability and functional ability of an equipment over time. Most construction sites follow a time-based maintenance schedule for pragmatic purposes and in compliance to conventional industry requirements. Figure 1 shows a comparison of the three broad types of maintenance strategies in the industry.

The figure shows a trade-off between the usable life of the machine and the potential cost incurred in the maintenance. It clearly states that the predictive maintenance strategy is the most suitable among the three strategies, considering the improvement in the useful life in a more cost-efficient manner. This ensures preemptive measures and utilization of the machine and its components apropos of the designed life. This also confirms a method most suited to address unforeseeable interruptions based on its immediate condition.

Predictive Maintenance or Condition Based Maintenance (CBM) is based on monitoring of the visible performance parameters that indicate the deterioration of the machine. Some of these parameters for a drilling machine include vibration threshold, Rate of penetration (ROP), and temperature rise. Vibration-based condition monitoring can facilitate early detection of the problem, improve maintenance procedure, and avoid catastrophic failures which will ensure fullest functionality and uninterrupted usage of the machine [7]. CBM ensures that each component receives customized care, which also addresses the overall health and smooth functionality of the machine.

Potential of IoT technologies

Recent studies have shown the potential of sensor integrated automated systems to address abrupt impediments and perform customized micromanagement of machines. The systems find a variety of applications in the field of personnel management, prefabrication, material management, and enhancing safety and quality at construction sites [8]–[10]. These systems allow detecting, analysing, measuring, and processing various changes like change in position of resources, the dimension of a facility, and textural appearance that occur in construction sites. Practitioners have appreciated the contribution of IoT based systems for batching plant monitoring, diesel generator utilization, and asset tracking systems for heavy machinery such as tower cranes, transit mixers, and trucks.

Moreover, applications such as early flood detection (warning) system, predicting the location of workers in construction sites are thought-provoking ideas that can be utilised for efficient construction management. As most of the work in the field of IoT is focussed in monitoring the heavy machinery, workforce management, inventory management, and progress forecasting, power tools have been almost kept out of the scope of the IoT implementation. Hilti Corp., Trackinno, Qubes, and BOSCH are some of the pioneers in the field of automated power tool management system but most of the innovations in this field serve administrative purposes. These include maintaining a database of the tool, automatic utilization reports, and warnings about the preloaded maintenance schedule [11]–[13].

In Construction 4.0, an automated CBM framework can facilitate real-time health monitoring of the machine without any human intervention. This will reduce the chances of errors due to human involvement, such as delayed, misinterpreted, and manipulated information. IoT enabled system frameworks can enable real-time data transmission from the machine to the managers. The use of appropriate sensors is a crucial aspect of any IoT system for customized control and overall functionality. Understanding the behaviour of Micro-ElectroMechanical Systems (MEMS) and the characteristics of an accelerometer or gyroscope allows designers to design more efficient and low-cost products for high-volume applications [14]. Various types of sensors, like RFID sensors, sound, and vibration sensors can discover the changes in the patterns of the data and can be part of an effective warning system, connecting each machine component to the overall machinery.

The selection of suitable sensors is a vital part of an IoT system, which integrates information and preemptive action through triggers and warning signals. There are various types of sensors ranging from a simple temperature and pressure sensor to a very sophisticated MEMS sensor such as MPU6050 and ADXL345, which can be selected based on specific situational requirements. Studies show that MEMS sensor-based systems have the potential to transfer the data over a network to an IoT platform using micro-controllers and Wi-Fi connectors [15]. The current study tries to create a warning system based on the real-time vibration values from the tool.

The literature on various IoT based frameworks shows that some of the major challenges in the implementation of IoT based system are privacy, security, and power consumption requirements of the system. The dynamic, complex, and often unpredictable nature of the environment at a construction site is also considered to be one of the major challenges along with the interoperability of different data formats, extendibility, and middleware challenges such as reliability and usability [16]. Some of the researchers have identified and argued that the failure of the IoT implementation could be attributed to scalability, adaptability, connectivity, maintainability, and inter-compatibility of the IoT components [17]. The current study averts the compatibility issue by identifying the resources that are fulfilling the requirements of the layers of a typical IoT system architecture. In the process, it aims to offer a reliable and elegant model where the practical impediments can be addressed and redressed at low cost.

Multi-layered Architecture

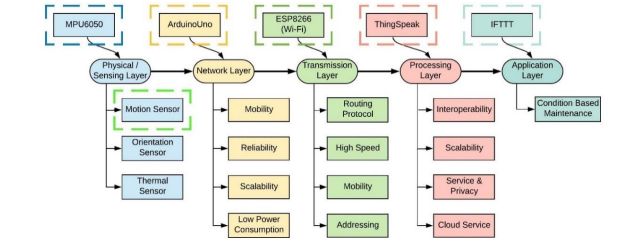

A brief description of the architecture is as follows:

Physical / Sensing Layer

This layer senses the data through various sensors. It uses MPU6050, an MEMS sensor that measures acceleration, velocity, orientation, displacement in addition to the temperature sensing. This study uses the acceleration readings only, however angular and thermal sensing can add to the value and space utilization of the sensor over others. The “InvenSense document for the specification of MPU6000 and MPU6050” provides information about the connections and the key pin-values. The sensitivity of the accelerometer can be adjusted between ±2g to ±16g, to customize the requirement.

Network Layer

This layer acts as a communicator and transfers the data to the network through the Wi-Fi module. It uses ArduinoUNO, an open-source microcontroller which is equipped with pins for digital and analog input/output data. The sensor and the Wi-Fi module are connected to the Arduino by jumper wires. Arduino collects and transmits the data as per the code written in the IDE (Integrated Development Environment) [18]. The IDE is a cross-platform application that supports coding in most of the computer languages such as java, python, MATLAB, C, or C++. The necessary codes are available on github.com, which can be modified and be uploaded in the editor. The system should meet the minimum requirements to use the Arduino editor smoothly [19].

Transmission Layer

This layer comprises of a Wi-Fi module that transfers the data over the network without the use of any cable or direct communication material. In the current study, ESP8266, an economic Wi-Fi module is used that transmits the data to the IoT platform. The major impediments to the effective functioning of the module is poor network connectivity and volume of data being transferred. The quality network connectivity can affect the time in transferring the data and thus affect the overall functioning of the entire unit

Processing Layer

This layer contains an IoT platform that is designed to enable a symbiotic relationship between the functioning machines and the maintenance personnel. ThingSpeak is chosen as the IoT platform here, which is an open-source platform and allows a more flexible and interactive interface. Real-time data collection, data analysis, data processing, data visualization, and message transmission are some of the key features of this platform. It is an intuitive, interactive, and inclusive operating system accommodating a wide range of user interfaces enabling a reliable monitoring environments such as C, Node.js, Python, and MATLAB.

Application Layer

This layer facilitates actuation from mobile or webapplication for the end-users. IFTTT is a freeware webbased service that triggers the notification as soon as a certain condition is met. It uses real-time APIs (Automated Program Interface) to trigger the event and execute the action [20]. It can thus on auto-pilot mode and generate unique and relevant responses addressing complex and fast-changing situations. It also minimizes human intervention and the errors that can emerge from the same during dysfunctional moments that can potentially create disasters and hazards at workplace.

Flow of data

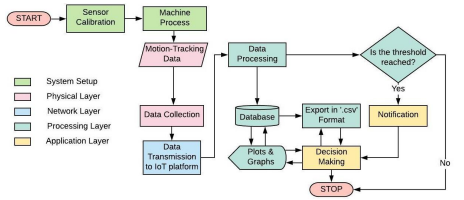

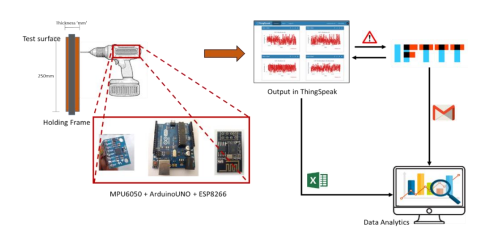

After identifying the resources for the study, a framework for the flow of data is necessary. Figure 3 shows a schematic diagram for the flow of data from the point of sensing to the point of notification. The diagram also considers the function that is to be performed in conjunction with each IoT ecosystem layers. This subsection explains interactions and interconnectedness among the various resources and the unique roles they play in the proposed framework.

MPU6050 sensor senses the three directional motion of the machine.

ArduinoUNO acts as a communicator for storing and transferring the data to ‘ThingSpeak’ through Wi-Fi module ESP8266 and data customization as per the application. The ArduinoUNO coding uses I2C library for transmission and easy functioning. ThingSpeak allows us to create channels to visualize the data. The data is transferred to the channels using the respective APIs, which ensures that correct data is used for analysis. Moreover, ThingSpeak has an integrated ‘Predictive Maintenance Toolbox’ that facilitates the deployment of an analytical algorithm. A suitable algorithm can be used for estimating the Remaining Useful Life (RUL) of the machine.

Another web-based freeware service IFTTT enables to create an event in order to run the system in real-time. The event includes the HTTP link of the ThingSpeak channel, threshold value, and the message that is to be displayed while notifying. The notification can be sent through Email or SMS. As soon as the threshold condition is met based on the data analytics, IFTTT triggers the alarm to the O&M team for timely intervention and maintenance.

Experimental Methodology

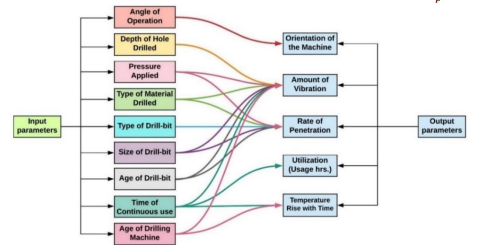

Having set up framework for the study, an experiment is designed to check the functionality of the proposed system. As already discussed, many performance parameters can be visible and reliable indicators of the machine’s health. Figure 4 shows the cause and effect of the parameters that affect the performance indicators of a machine. A drilling operation includes multiple changes in the working environment of the machine. It can be understood from the literature and discussions held with the practitioners that one of the most explicit and easily recognisable indicators of the health of a machine is the amount of vibration produced.

The amount of vibration largely depends on the age and size of the machine and drill-bits, the pressure applied while drilling, type of material drilled, and continuous usage of the machine. Process instabilities and wearing out of the cutting tool can be easily recognised by the changes in vibration patterns.

The interdependency of the indicators, as shown in Figure 4, allows us to explore further the effect of these input parameters on the performance indicators. Based on the discussions, the scope of the current study is limited to the accelerometer readings only, but the framework presented is theoretically applicable to all sensor-based systems with a suitable selection of sensors

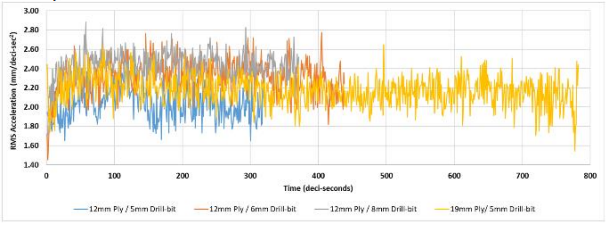

The experimental runs were conducted for various combinations of varying drill bit diameter (D: 5mm, 6mm, and 8mm) and plywood thickness (T: 12mm and 19mm) to check the variations in the acceleration produced in the machine, Rate of Penetration (ROP), and Time of Penetration. Figure 5 shows a schematic diagram for the proposed experimental setup.

The sensor-system comprising of MPU6050, ArduinoUNO, and ESP8266 is attached to the drilling machine. The material to be drilled is fixed in a firm place to prevent its movement. The sensor-system transmits the data to the ThingSpeak platform, which plots graphs, displaying the real-time acceleration produced in the three directions. Once the acceleration crosses the threshold (pre-fixed value), a warning is sent to the maintenance engineer for action. The data can also be downloaded in ‘.csv’ format for records and further analysis. Thus, this model allows innovative intervention as well as archiving of data for production of templates that may be drawn on for future references.

Data Processing

Statistical Process Control (SPC) suggests the minimum number of data points to check the appropriateness of the experiment in Eq. (1): 𝐴𝑅𝐿 = 1/𝑝.

37th International Symposium on Automation and Robotics in Construction (ISARC 2020)

For ±3σ control limits, p = 0.0027. Substituting value of ‘p’ in in Eq. (1) we get, ARL = 370 data points [21]. The trial runs were conducted for different D-T combinations to estimate an average penetration time for each combination. The code (ArduinoIDE) is adjusted so that the number of points is not less than 370. A drilling run is continued until the hole is perfectly penetrated. As the individual resultants in the three directions may not justify showing the real motion produced in the machine, the Resultant (R) of the three accelerations is calculated using Eq (2) :

The threshold value or the control limit (±3σ) for a DT combination is determined from the RMS value of acceleration. For the scope of this study, the ‘+3σ value’ is fixed as the threshold value to trigger the warning for maintenance. The trigger request is completed with a ThingHTTP, which initiates the predefined HTTP requests with an API key. Additionally, a GET request from the web when the threshold is reached and triggers the Webhooks at IFTTT which sends an Email with a customized message prompting immediate action. Similarly, runs were conducted for the various D-T combinations and the free run condition. The results are discussed in the next section.

Results

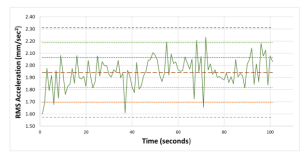

The experiments were performed for various D-T combinations, and the results are shown in Figure 6 and Figure 7. Figure 6 shows the RMS Acceleration for a free run condition that gives a reliable idea about the inherent vibration in the machine when in operation. Figure 7 depicts a comparison of the ranges in which the value of RMS acceleration lies for the different D-T combinations.

The receipt of data on the IoT platform and the triggering of the Webhooks event named “Threshold Reached!” confirms that the proposed framework performed as expected. Figure 8 shows screenshots of the creation of ThingHTTP and warning received.

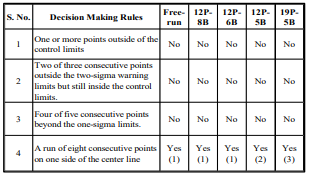

The quality of the data is checked using the ‘Western Electric Rule’, the results of which are summarized in Table 1. These rules are in accordance with the statistical norms and suggest that the quality of data is controlled under experimental as well as industrial conditions [21]. As there are no outliers in the plots, this explains the potential of the system to be used in sophisticated and controlled experiments across various situational frames.

Discussion and Conclusion

The smooth functioning of the proposed system architecture and components validate the functionality of the system for the current scenario. This study facilitates the implementation of an effective IoT system for realtime health monitoring of a hand-held drilling machine. Testing the acquired data against the Western Electric Rules suggest that the quality of the experiment was controlled, and the exhibited framework can be used for a variety of applications in accordance with the selection of appropriate sensors. The successful functioning of the framework ensures that the tools can be monitored continuously and remotely through an inexpensive system, which is also practically easy to maintain.

The experimental setup plots the real-time acceleration data from the machine while in operation on an IoT platform. Vibration is one of the visible performance indicators of the machine’s health, and can be used in the study of Machine Prognostics. This involves the estimation of RUL of the machine, which is a well-framed four-staged procedure. The process includes Data Acquisition, Health indicators (HI) construction, Health Stage (HS) division, and finally the RUL prediction. Various approaches, such as the statistical model-based (Random co-efficient, AR models, etc.), AI approach, Physics model-based approach, have been developed to display various strategies to predict the RUL [22]. The selection of an approach for RUL estimation is based on the type of application. For the scope of the current study, the RMS value of the resultant acceleration is considered as the threshold value for triggering the warning system

Furthermore, the ThingSpeak platform has an integrated Toolbox for Predictive Maintenance supported by MathWorks. An appropriate algorithm can be deployed on the cloud using ThingSpeak and MATLAB prediction server to estimate the real-time RUL. This will monitor the health of the machine and warns once the threshold is achieved. These thresholds can be specific to the type and make of the machine. The presented framework facilitates keeping track of the used life of a machine, which is useful during the inter-site transfer of the machine. This can also enable the site management to have stricter surveillance over the hand tools and make more informed and intelligent procurement strategies.

Preliminary analysis should be conducted to decide the position of the sensor on the equipment, as the vibration data obtained will be sensitive to it. In this study, the sensor was attached based on the driller’s convenience, at a place where it was assumed that the vibration is maximum. In some cases, the limited connectivity at construction sites due to the remote location is a challenge for the proposed architecture as it may result in delayed information due to the restricted transfer of data across the interconnected layers.

The predictive approach showcased here is expected to save a considerable amount of time, cost, and effort than what is conventionally required in the reactive or preventive approach. It will also allow end-users to utilize the machine up-to its design life. The system can be an appropriate tool for the manufacturing industry to design the components having similar operational lives. The potential of advances in Machine Learning and Artificial Intelligence in conjunction with moresophisticated sensors such as Hall sensor and tip-pressure sensor can make the system more robust and extensive. Further more, the system is expected to flourish with a substantial amount of data coming from the industry and using more advanced degradation models of ML learning integrated with AI. This study can be a robust and elegant template for future research on maintenance strategies