Texas toll manufacturer Texmark Chemicals is a crucial link in the petroleum product supply chain, and because it works with regulated hazardous materials, safety is a top priority. So it turned to HPE, CB Technologies and an industry-leading Partner Consortium–including Aruba, Deloitte, Intel, PTC, National Instruments and more–to build a Refinery of the Future featuring advanced Industrial IoT capabilities. The results: better process analytics, increased up-time, uninterrupted productivity, satisfied customers, and safer, connected, workers.

Hot demand for a hot product

Demand for dicyclopentadiene (DCPD), a polymer precursor for everything from ink to boats, is growing worldwide. But DCPD manufacturing processes involve flammable materials requiring stringent safety measures—and as demand increases, so does the complexity of the supply chains that rely on it.

The ink in a printer. The hull of a fiberglass boat. A bathtub. Manufacturing these products as well as many others including adhesives, paints, varnishes, fragrances, and rubber goods, requires the polymer precursor dicyclopentadiene (DCPD) or a derivative of it

Manufacturers like DCPD because it makes products tough, able to resist heat and corrosion. Worldwide demand for DCPD is growing, driven by the producers of resins and plastics, and the needs of the marine and construction industries. In the United States and Europe, the uptick is coming from recovering economies. In the Asia Pacific region, the product is needed by a growing plastics industry. Demand also is rising in Latin America and Africa.

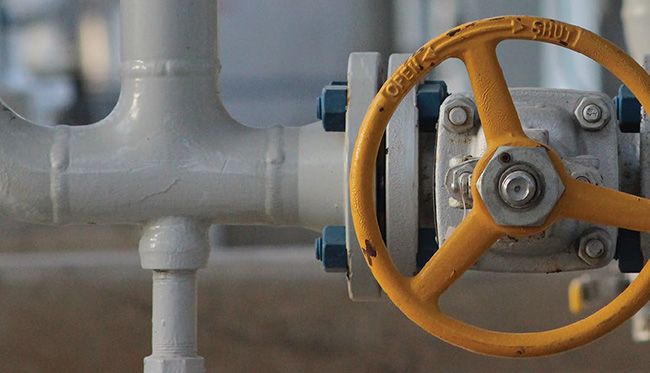

But manufacturing and supplying DCPD and related products isn’t simple. Its manufacture involves heat—lots of it— and highly reactive chemicals, making safety a top priority. This requires ever more stringent controls, granular visibility, and regulatory oversight. And as demand for DCPD grows, the need for increased productivity becomes paramount.

6.1%

Compound annual growth rate worldwide in DCPD market1

$902.3M

A Petro-Chemical industry benchmark for quality and safety

Texmark Chemicals of Texas is a leading producer of DCPD, and an industry benchmark for quality and safety.

Texmark Chemicals, Inc., is a Texas Petro-Chemical processing and manufacturing company that provides custom contract manufacturing (tolling) of specialty and high volume chemicals to many of the world’s leading chemical companies.

Texmark is the #1 merchant producer of DCPD in North America. Access to the Houston Ship Channel allows Texmark to ship and receive products by ship and barge, as well as by rail and truck. With its advanced equipment and strict process controls, Texmark has been an industry leader in quality and safety for nearly 50 years.

“Texmark makes chemicals for the world. For nearly 50 years, we have been the benchmark of quality in our industry. At Texmark, safety and people come first—our employees, our customers, and our neighbors. – David Smith, Founder, Texmark Chemicals

Stay safe, drive efficiency, satisfy customers

Safety comes first when dealing with flammable, highly regulated materials. Operational efficiency and a long-term vision are essential to keep market leadership.

Texmark’s first business priority is safety. It works with hazardous, flammable, and heavily regulated materials. Texmark must ensure its procedures, facilities, and operations put worker and community safety first, at all times

As a contract manufacturer, Texmark must be prepared to adapt to customer requirements, which can change with little advance warning

It must also drive continual plant efficiency and productivity, while maintaining the integrity of industrial assets. Historically, Texmark has inspected equipment through time-consuming and labor-intensive plant walk-downs. These rely on employees who—based on years of experience—can recognize malfunctions through slight variations in pump noise and vibrations. Depending on this scarce human expertise carries a business risk. Texmark needs ways to institutionalize knowledge.

Lastly, Texmark has to keep the leadership in a highly competitive market. How can an 80-year-old plant evolve to stay in business for the next 50? When Texmark first asked this question, it soon realized insights from assets, employees, and industry experts were key to building a visionary answer

The global business environment in the petrochemical industry is very, very competitive. We’re constantly seeking ways to compete more effectively. And any approach we take must also align with our commitment to ethics, safety, and community – Doug Smith, CEO, Texmark Chemicals

Bring IIoT vision into the reality of operations

IoT promises enhanced worker safety, production and asset management. But specialized manufacturing needs more than one-size-fits-all solutions or a conservative approach.

Texmark’s vision hinges on the promise of the Industrial Internet of Things (IIoT): sensored devices combined with advanced analytics to generate insights, increase efficiency, and reduce risks.

But implementing IIoT in a petrochemical plant requires a unique infrastructure. Connectivity must be ubiquitous, but hard-wiring facilities can be prohibitively expensive. Texmark’s edge environment demands ruggedized technology and stringent safety standards. Seconds count in manufacturing. To avoid data latency, analytics have to be delivered at the edge.

To integrate IT with its operations, Texmark had to digitize pumps, pipes, processes and utilities. The effort required the expertise of more than a dozen vendors, and a cultural shift for its own employees.

To achieve its vision of an intelligent plant, Texmark needed a bold, multi-pronged approach: define the most valuable use cases, match those with the right technologies, and deploy simultaneously, without disrupting 24/7 plant operations

“We brought employees to see the HPE IoT lab. They saw the art of the possible and had ideas about what we could do at Texmark right away. The engagement, the buy-in was there from the beginning.” – Linda Salinas, Vice President of Operations, Texmark Chemicals

An IIoT journey, hand in hand with HPE and its partners

Texmark embarked on a three-phase IIoT journey, bringing together a Partner Consortium to create an industry-leading Refinery of the Future

Texmark launched a project to implement end-to-end IIoT. It leveraged the expertise of CB Technologies to integrate IIoT technologies from HPE, Aruba, and an extensive list of industry-leading partners. First, Texmark established a digital foundation, enabling edge-to-core connectivity. Aruba deployed a secure wireless mesh network, with Class I Div 1 wide area access points and ClearPass for access control. Aruba beacons provide location-based services. The wireless solution came at about half the cost of a hardwired network

For edge analytics, Texmark selected the HPE Edgeline Converged system, an IoT platform ruggedized for manufacturing environments. An HPE Edge Center solution integrates compute and networking within a single cabinet. The system is connected to Texmark’s control room, edge devices, and sensored assets such as pumps, enabling real-time data collection and analytics. It also receives data from Texmark’s Distributed Control System software, integrating OT and IT

This infrastructure now serves as the backbone that supports Texmark’s five solution frameworks: Predictive Maintenance and Analytics, Video as a Sensor, Worker Safety and Security, Connected Worker, and Asset Integrity Management.

As the official Systems Integrator and IT Support Contractor for the entire project, CB Technologies orchestrates technologies on behalf of the Partner Consortium and maintains Texmark’s IT systems as the solution frameworks are deployed and integrated.

The Partner Consortium includes HPE, CB Technologies, Aruba, Deloitte, Intel, PTC, and many others. These partners collaborate on the different solution frameworks, enabling the simultaneous deployment and unification of a wide range of hardware, software, and OT.

“We’re building a refinery of the future that combs through data and reveals how the entire plant is interconnected. It becomes like a living, breathing organic plant that knows how it should operate; if any part falls out of line, it flags for intervention.” – Linda Salinas, Vice President of Operations, Texmark Chemicals

A showcase refinery of the future

Automated worker safety, facility condition monitoring, and predictive maintenance bring transformational innovation, efficiency, and protection.

This custom-designed IIoT solution makes Texmark’s workers and community even safer. By monitoring pump conditions— pressure, temperature, vibrations—potential malfunctions are immediately detected and notified, allowing a response before workers or production are endangered. Video analytics provide automated, cost-effective point-of-entry surveillance. And in case of emergency, insights from varied sources—geolocation, alarm system, weather conditions—can help determine the safest response.

The solution empowers employees to respond faster and reduce manual, repetitive tasks to focus on higher value activities. Realtime insight from sensors, combined with historic data and machine learning, are turned into actionable dashboards, personalized to each role. Operators can access the data they need, when they need it, through mobile devices and hands-free, voice activated wearables, and via HPE Visual Remote Guidance enterprise, secure software

Digitization also helps attract talent and new business. At Texmark, employees know they are safer and can develop a futureproof skillset, while toll customers benefit from streamlined processes, valuable data, and better SLAs.

The company’s bottom line will also be improved through maintenance savings and increased production uptime. IIoT and predictive analytics help identify which systems require hands-on attention. And Texmark can conduct more focused and efficient inspections, plan maintenance to reduce downtime, and extend the life of equipment.

Texmark’s visibility of its plant keeps expanding. By adding AI, asset tracking, and ERP interconnection to its 3D plant model and mechanical integrity software, the company will come closer to its vision of an intelligent, unified system.