The high-tech issue is the early identification of performance degradation of machinery in production processes.Vibration coming from component wear in the bearings and rotating shafts of industrial assets is the key performance parameter and ideally it needs to be monitored 24/7.

At first sight this would seem to be a simple task, but production plants around the world employ numerous mixers, centrifuges, pumps, motors, air compressors, fans and conveyors. It is clearly impractical to stop production and install sensors in legacy machinery, so right now handheld devices are used to measure vibration.

Typically they collect data at pre-set intervals, e.g. every 4-6 month, a report is sent to the asset owner usually within a week, says Bob Emmerson, freelance writer and IoT Industry Observer.

There are other devices that transfer data via Bluetooth to a smart phone for interpretation by the engineer or maintenance team. Manual labour is involved in both cases. Apart from being a somewhat clumsy process, real-time data is needed in order to predict upcoming performance problems and costly breakdowns.

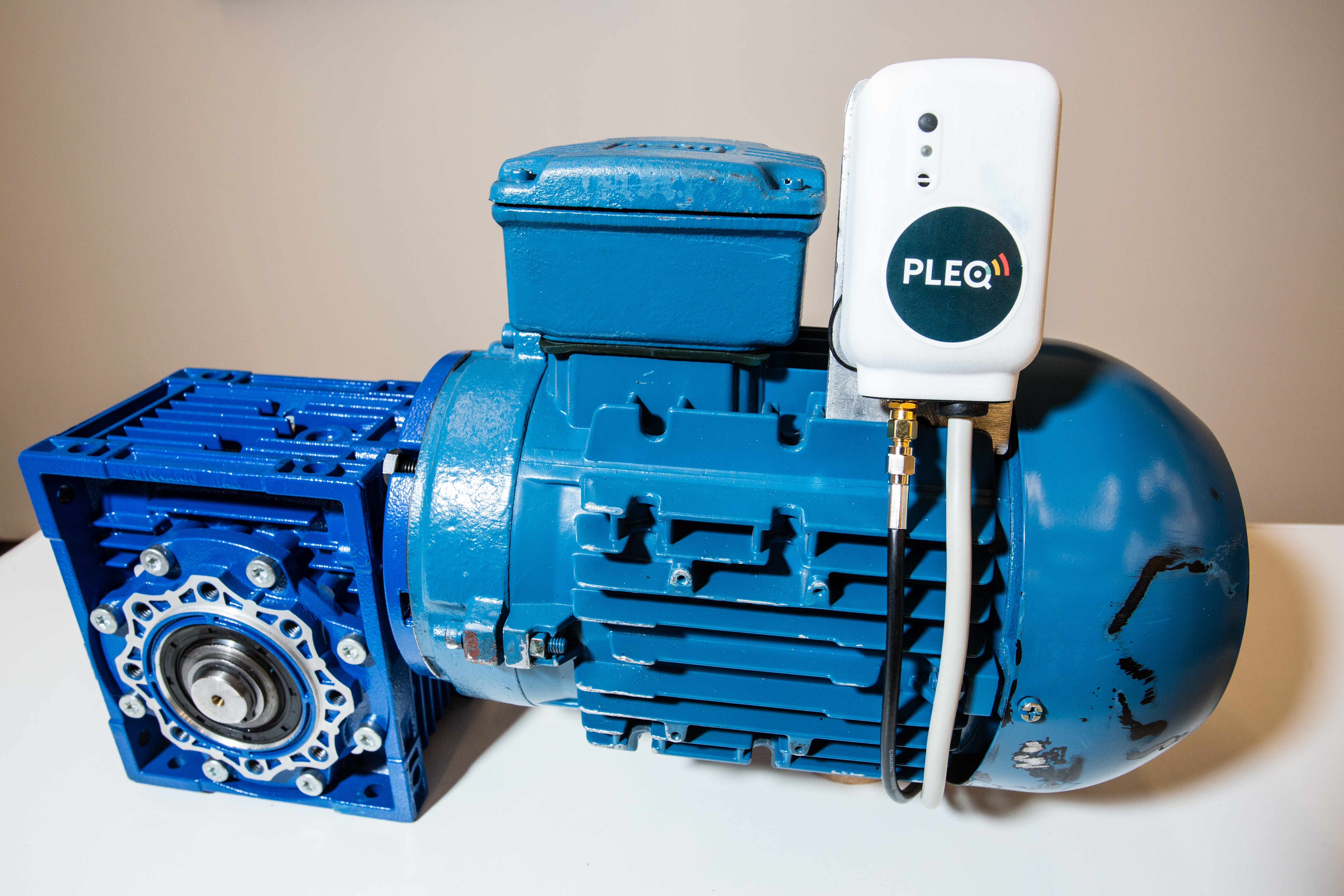

The pragmatic response from PLEQ is simple but very effective. As illustrated, the company has developed a robust, smart sensor that attaches to the casing, which makes it easy to retrofit to legacy assets. It supports both vibration and temperature monitoring out of the box. Vibration data is provided by a 9-axis measurement MEMS accelerometer, which provides full-resolution sampling thereby giving accurate insights into root-case effects.

This solution opens up the market for the company’s feature-rich predictive maintenance suite that targets small- and medium-sized enterprises. Real-time telemetry, adaptive analytics engine and simple reporting structures enable performance insights that provide new opportunities for predictive maintenance.

When a database of failure signatures has been be built up the solution will enable users to transition from predictive maintenance to fully prescriptive maintenance, not only alerting them of imminent failures, but also the measures that should be taken to extend the life of the asset.

After the device is mounted and powered, a secure connection to the PLEQ Cloud allows data communication at set intervals, on-demand or when significant change occurs. It’s an out-of-the box preventative maintenance solution that provides 24/7 monitoring and failure reporting with support for alarms, notifications and analysis.

After the device is mounted and powered, a secure connection to the PLEQ Cloud allows data communication at set intervals, on-demand or when significant change occurs. It’s an out-of-the box preventative maintenance solution that provides 24/7 monitoring and failure reporting with support for alarms, notifications and analysis.

The author of this blog is Bob Emmerson, freelance writer and IoT Industry Observer

Comment on this article below or via Twitter: @IoTNow_ OR @jcIoTnow