There was a lot of talk about Industry 4.0 and smart factories in 2016. Since then the cost of

connectivity – through the efforts of the LoRa Alliance and developments in the cellular technology

NB-IoT, for example – and of sensors have fallen dramatically. But how much progress have we made

towards those goals? What have we learned and where are the roadblocks, asks Annie Turner

Let’s recap: Industry 4.0 describes the next era of industrialisation also known as the fourth Industrial Revolution. The first revolution was the beginning of mechanisation, powered by steam. The second was the transformation electricity brought to manufacturing and the third was the impact of IT and the start of automation. The fourth is envisioned as having more intelligence, connectivity and computing to create smart factories.

According to the author and speaker Bernard Marr, manufacturing must include the following to qualify as Industry 4.0:

- have machines, devices, sensors and people connected and communicating;

- the systems creating a virtual copy of the physical world, based on data from sensors to put information into context;

- systems supporting humans in making decisions and solving problems, and especially with tasks that are too difficult or dangerous for people; and

- the cyber-physical systems learn as they go along, allowing them to make simple decisions and become as autonomous as possible.

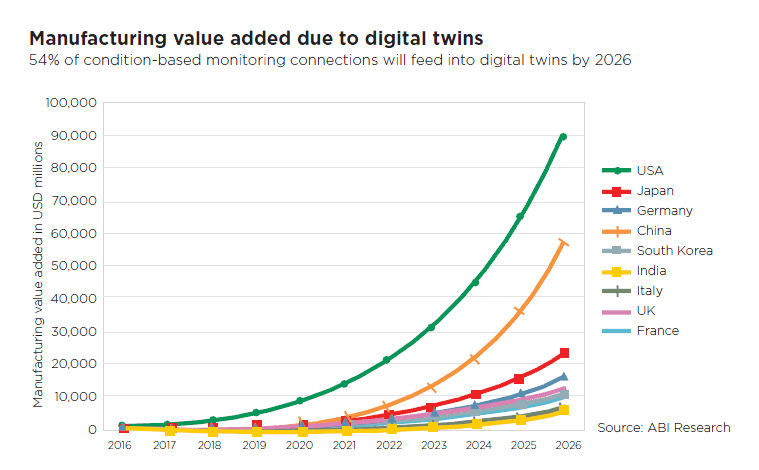

This is about operations, not the business case which has proved a stumbling block for many. Now, after many pilot schemes, only some of which were successful, expectations about what can be achieved and how quickly have become more realistic. Perhaps the biggest example of this realism is that the initial exuberance of GE – that most famous cheerleader for IoT and industrial digitisation – has worn off. The chief executive who launched GE Digital and declared the company’s aim of being a global top ten software developer by 2020 is gone. His successor acknowledges the importance of digitisation but has cut GE Digital’s budget by a quarter and shifted its focus to outcomes from specific applications – like asset tagging and managing field forces, which are hardly revolutionary – rather than grand designs, and more advanced uses such digital twins, which are here to stay, but making only steady progress – see graph opposite.

At the IoT TechExpo Global 2018 in mid-April in London, the consensus was companies are concentrating on how IoT can improve productivity and efficiency – evolving what they do already, rather than new business models and disruptive innovations. As Maciej Kranz, the vice president of Strategic Innovation at Cisco, says, “The real payoff from IoT comes down to automating existing processes that have a large labour or time component and streamlining the related process in one way or another.”

At the IoT TechExpo Global 2018 in mid-April in London, the consensus was companies are concentrating on how IoT can improve productivity and efficiency – evolving what they do already, rather than new business models and disruptive innovations. As Maciej Kranz, the vice president of Strategic Innovation at Cisco, says, “The real payoff from IoT comes down to automating existing processes that have a large labour or time component and streamlining the related process in one way or another.”

The big questions are how and when. Bernd Gross is the senior vice president for IoT and Cloud at Software AG, which last November teamed up with Siemens to promote Siemens’ MindSphere – a ‘cloud-based open Internet of Things (IoT) operating system for industries’. He says that there has been enough activity, “to identify certain patterns for successful projects.” These are the critical steps he outlined:

- the first stages are data-driven actions. Gross stresses, “The key is not to integrate before you stabilise or you could just have a different point of failure. If you implement too fast and change processes, they can become unreliable and you have end-to-end failures.” Gross advises companies to start with discrete applications such as alarm management.

- step two is about integrating the data-driven processes and moving to real-time to achieve new levels of efficiency.

- step three is when you should look to implement machine learning and artificial intelligence. Gross warns, “Too many projects look to do this before they’ve completed the other two steps. It can take 18 months before you have viable machine learning for your projects.”

He advises, “Take your time, develop your plans, enhance your capabilities, and learn about your new world at the integration part.”

How to balance this with the need for speed? Andreas Geiss, a vice president at Siemens, says, “Start the first step fast – now – and remember that success is not about the technology, but about having a data-centric business strategy.”

The Harley-Davidson Motor Company is a good example of starting with the problem to devise an IoT strategy. It was facing intense global competition. At the same time, its core market was aging and its products weren’t appealing to younger people. The firm’s labour costs were too high, production did not align with IT and there were islands of incompatible data everywhere, according to Cisco’s Kranz.

It’s success story started by a handful of key people talking to their opposite numbers in teams that in industries everywhere are known for being poor at cooperating and coordinating their efforts – operational technology (OT) and IT. The instigators asked more people to join and then formed a team charged with communicating their thinking to the wider teams and other business units about gaining as many efficiencies as possible from IoT.

Kranz says that some employees went so far as to swap jobs for a while to really understand the other’s issues. Now triage and troubleshooting, which used to create huge delays, are typically sorted out in a morning. The operational improvement from this alone has dramatically improved efficiency, productivity, flexibility and agility, according to Kranz.

Further, the strategic business outcomes from the changes wrought by IoT include:

- 80% percent faster decision making due to enabling the workforce;

- dramatic reductions in costs and set-up times;

- continuous asset management, enabling better decision making;

- 6.8% increase in production throughput due to asset tagging;

- 10 to 25 times improvement in build-to-order cycle times – down from 18 months to two weeks; and

- a 7 to 12% increase in equipment use, driven by IoT-enabled automation.

In combination these improvements – from just one factory – led to an increase in the company’s profits of between 3% and 4%. Of course, the company’s other plants are keen to emulate and expand these developments.

Nothing breeds success like success, and as confidence grows in the outcomes IoT can deliver along with a better understanding of what makes a successful deployment, factories will become increasingly smart, ultimately with the smartest of all making a successful move from evolution to revolution.